The U.S. Department of Labor has taken significant enforcement action against Virginia Transformer Corp., citing the company’s Idaho facility with proposed penalties nearing one million dollars after an investigation by the Occupational Safety and Health Administration (OSHA) uncovered a shocking number of uncorrected and recurring safety hazards. This case highlights a disturbing pattern of failing to protect workers from serious, and potentially fatal, risks on the job. The core of the issue is not a first-time offense but a documented history of non-compliance. Federal inspectors found that the transformer manufacturer had been previously warned about specific dangerous conditions during inspections conducted in 2024. The company’s failure to take sufficient corrective action and abate these known hazards is the primary justification for the severity of OSHA’s response and the substantial financial penalty, which sends a clear message about corporate accountability in maintaining a safe working environment.

A Pattern of Negligence The Violations in Detail

Critical Failures in Heavy Machinery

The federal inspection yielded a comprehensive list of 53 distinct citations, which were classified by regulators as both “serious” and “repeat” violations. A “serious” violation is one where there is a substantial probability that death or serious physical harm could result from a hazard about which the employer knew or should have known. The “repeat” classification is even more damning, indicating that the company had been cited for the same or a substantially similar condition during a prior inspection, underscoring a systemic failure in its safety management programs. Among the most alarming findings were the repeat violations related to crane safety, a critical component in a facility that manufactures and moves massive transformers. Inspectors discovered that multiple cranes used to lift and maneuver multi-ton loads were operating with dangerously faulty brakes. In an industrial setting, a crane’s braking system is paramount; a failure can lead to a catastrophic load drop, posing an immediate and severe risk of fatal crushing injuries to any workers below.

The persistent nature of these machinery-related hazards points to a deep-seated problem within the company’s operational oversight. Beyond the defective braking systems, the control switches used by operators to guide the cranes were also found to be faulty. This deficiency can result in erratic, unintended, or completely uncontrolled movement of heavy equipment, making it impossible for operators to safely and precisely position loads. Such failures introduce a chaotic element into a high-risk environment, creating the potential for devastating collisions, crushing incidents, and widespread danger to personnel throughout the work area. The fact that these crane safety issues were flagged as repeat violations demonstrates that the company had been formally alerted to these specific dangers during inspections in 2024 but failed to implement lasting and effective corrective measures. This recidivism suggests a corporate culture where production may have been prioritized over the fundamental safety and well-being of its workforce.

Pervasive Dangers on the Factory Floor

The litany of citations extended well beyond heavy machinery, painting a picture of a facility where danger was present at nearly every turn. Virginia Transformer Corp. was cited for its widespread failure to properly guard machinery, a fundamental safety requirement designed to create a physical barrier between a worker and hazardous moving parts. The absence of these guards meant that employees were routinely exposed to unguarded points of operation, ingoing nip points where rotating gears or rollers meet, and other moving components. This constant exposure created a high risk for horrific and life-altering injuries such as amputations, deep lacerations, and crushing. OSHA’s findings indicate that workers at the facility were performing their duties in close proximity to these preventable risks on a daily basis, a clear violation of established industrial safety standards that have been in place for decades to prevent such tragedies.

Furthermore, inspectors identified significant fall hazards throughout the facility, another leading cause of death and serious injury in the American workplace. The investigation revealed that the company had neglected to implement required fall protection systems, exposing employees working at height to the constant danger of unprotected edges on platforms and walkways. These areas lacked standard guardrails or other barriers necessary to prevent a fall. The company also failed to provide personal fall arrest systems, such as harnesses and lanyards, for those working in elevated positions. Compounding these issues was a failure to provide or enforce the use of required Personal Protective Equipment (PPE). In a transformer manufacturing environment, equipment like hard hats, safety glasses, steel-toed boots, and protective gloves is not optional; it is the last line of defense against injury. This lapse left workers vulnerable to a wide range of injuries, completing a portrait of an unsafe work environment.

The Federal Response and the Company’s Crossroads

Holding the Employer Accountable

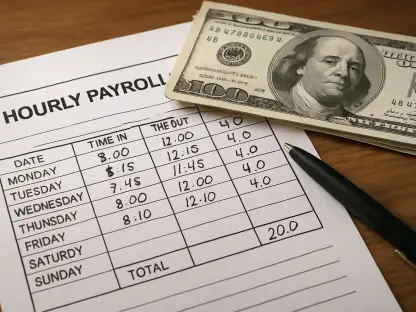

In a formal statement addressing the citations, the Department of Labor emphasized the non-negotiable legal and moral responsibility employers have to identify and correct hazards that place their workers in harm’s way. Officials pointedly noted that Virginia Transformer Corp. had been made aware of similar dangerous conditions during previous federal inspections but did not act decisively to implement permanent solutions. This history of inaction led directly to the proposed penalty of $986,888, a figure meticulously calculated to reflect not only the severity and quantity of the 53 violations but, most critically, their repetitive nature. The substantial fine is intended to serve as a powerful deterrent, sending an unequivocal message to this employer and the broader industry that a sustained disregard for federally mandated safety standards will result in significant financial consequences. The action underscores OSHA’s commitment to holding companies accountable for protecting their most valuable asset: their employees.

The regulatory framework that empowers OSHA to issue such significant penalties is designed to be both punitive and corrective. The primary goal is not merely to punish past transgressions but to compel a company to fundamentally reform its safety culture and prevent future incidents. The magnitude of a proposed fine is determined by a structured process that considers multiple factors, including the gravity of each violation, the size of the business, any demonstrated good faith efforts to comply with regulations, and the company’s history of previous violations. In this instance, the history of repeat violations was a major aggravating factor, dramatically increasing the penalty amount. This approach ensures that the financial consequences are proportional to the degree of negligence. By levying a penalty of this scale, federal regulators are signaling that the cost of non-compliance will far outweigh the expense of implementing and maintaining a robust safety program, thereby incentivizing proactive hazard abatement across the industry.

A Critical Decision Looms

Following the formal issuance of the citations, Virginia Transformer Corp. was placed under a strict 15-business-day deadline to determine its course of action. This period marks a critical juncture for the company, as its decision will not only impact its financial standing but also define its future relationship with federal regulators and its public commitment to workplace safety. The first and most direct option available was compliance. This path would involve accepting the entirety of OSHA’s findings, paying the full proposed penalty of nearly one million dollars, and providing verifiable proof to the agency that all 53 identified hazards had been thoroughly and permanently abated. Choosing this option would represent the quickest route to resolving the immediate legal issue, but it would also serve as a formal admission of the extensive safety failures detailed in the inspection report, which could have further legal and reputational ramifications for the corporation.

The company also had two alternative paths it could have pursued within the allotted timeframe. The first was to request an informal conference with the OSHA Area Director. This meeting would have provided an opportunity to discuss the violations and penalties, present any mitigating evidence or documentation of good faith efforts, and potentially negotiate a settlement agreement. Such agreements often involve a reduction in penalties in exchange for a swift and comprehensive abatement plan that goes above and beyond the minimum requirements. In contrast, the most adversarial option was to formally contest the findings before the Occupational Safety and Health Review Commission (OSHRC), an independent adjudicatory agency. This action would have initiated a formal legal process, akin to a lawsuit, to resolve the dispute. The path Virginia Transformer Corp. ultimately chose reflected its stance on the federal findings and set the precedent for its commitment to ensuring a safe workplace moving forward.